Product Info.

Nan Ya Plastics Corporation, America, South Carolina Plant has an annual production capacity of approximately 2 billion pounds of polyester. Our highly automated processes effectively combine Asian, European, and American design, allowing us to benefit from worldwide technology. Through employee training and optimization of processes, we are continually striving to provide customers in the textile and packaging industries with the highest quality products possible. ISO9001 certification and other management programs provide a foundation and driving force for continual improvement.

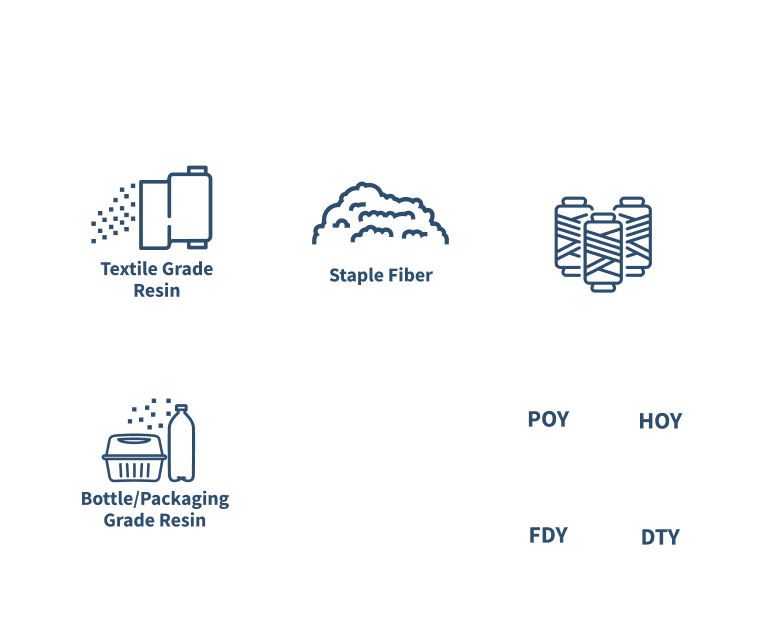

PRODUCT SCHEMATIC